MCG Transportation

MCG obtém Certificação IRIS – ISO/TS 22163:2017

A certificação International Railway Industry Standard coloca a MCG Transportation ao nível dos melhores fornecedores mundiais do sector ferroviário.

MCG Automotive

'A participação da MCG é fundamental para aprimorar este programa de descarbonização.'

Miguel Araújo, Diretor Geral da Mobinov, explica as bases do Roteiro de Descarbonização do Sector Automóvel Nacional.

MCG Stories

'Manter elevados níveis de qualidade é essencial.'

Daniel Bento, Supervisor do Laboratório de Qualidade da MCG, partilha connosco a forma como encara os vários desafios diários que a empresa lhe coloca.

MCG I&D

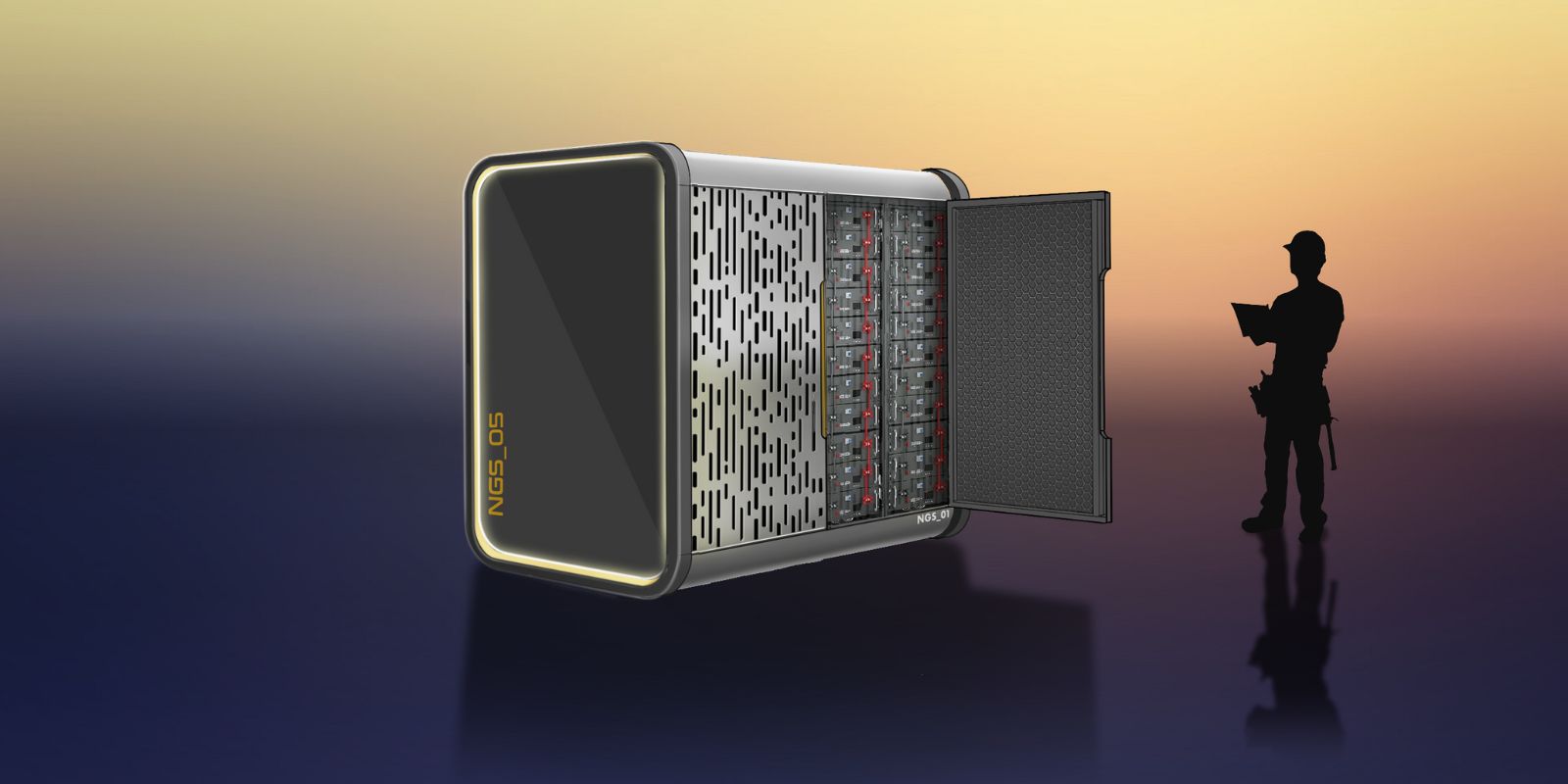

MCG integra consórcio do projeto NGS – New Generation Storage

Para ajudar no desenvolvimento de um novo ecossistema tecnológico na área das baterias que irá destacar a indústria nacional no mercado global.

MCG Experiences

Colaboradores MCG testam o Volkswagen T-Roc

O contacto direto com o automóvel para o qual produzem componentes diariamente e a visita à Volkswagen Autoeuropa.

MCG Automotive

Processos robotizados cost-effective e de alta performance na produção de componentes

MCG Industry

Parcerias de engenharia e produção com o cliente

A CountR conta com a MCG e colabora com as equipas MCG para projetar, fabricar e aperfeiçoar a nova geração de máquinas de casino CashIO Titanium.

MCG Automotive

Investir em tecnologia, pessoas e processos

Para uma relação cada vez mais sólida com alguns dos maiores fabricantes de componentes automóveis do mundo.

Segurança na MCG

MCG Segurança Primeiro em 2023

A prioridade principal na MCG: zelar pela Segurança e Bem-Estar de todos seus Colaboradores.

História

Manuel da Conceição Graça teria completado 100 anos a 17 de Abril

Em "conversa" com o fundador da MCG, o CEO José Graça Medeiros fala da evolução da empresa e revela o que se segue: o início da concretização do novo Parque Industrial Manuel da Graça.

Áreas de Negócio

Notícias

MCG automotive

∙

Soluções MCG Automotive na produção de componentes para assentos de automóveis elétricos

Ler notícia

MCG Stories

∙

'É esta a essência da MCG, esta empresa é uma grande escola.'

Ler notícia

MCG Stories

∙

'As nossas funções enquanto Teamleaders também envolvem trabalharmos a felicidade dos outros.'

Ler notícia

MCG transportation

∙

Novos ensaios na produção de pisos para comboios de alta velocidade

Ler notícia

MCG transportation

∙

MCG transportation: nova cabine de colagem de pisos para comboios e autocarros

Ler notícia

MCG Stories

∙

MCG recebe Certificação DGERT na área da Formação Profissional

Ler notícia

Anterior

Anterior

Seguinte

Seguinte