MCG Transportation

MCG obtains IRIS - ISO/TS 22163:2017 Certification

The International Railway Industry Standard certification places MCG Transportation among the world's top suppliers in the railway sector.

MCG Automotive

'MCG’s participation is essential to improve this decarbonization program.'

Miguel Araújo, General Director of Mobinov, explains the basis of the Portuguese Decarbonization Roadmap for the National Automotive Sector.

MCG Stories

'Maintaining high levels of quality is essential.'

Daniel Bento, MCG Quality Laboratory Supervisor, shares with us how he faces the daily challenges the company presents to him.

MCG I&D

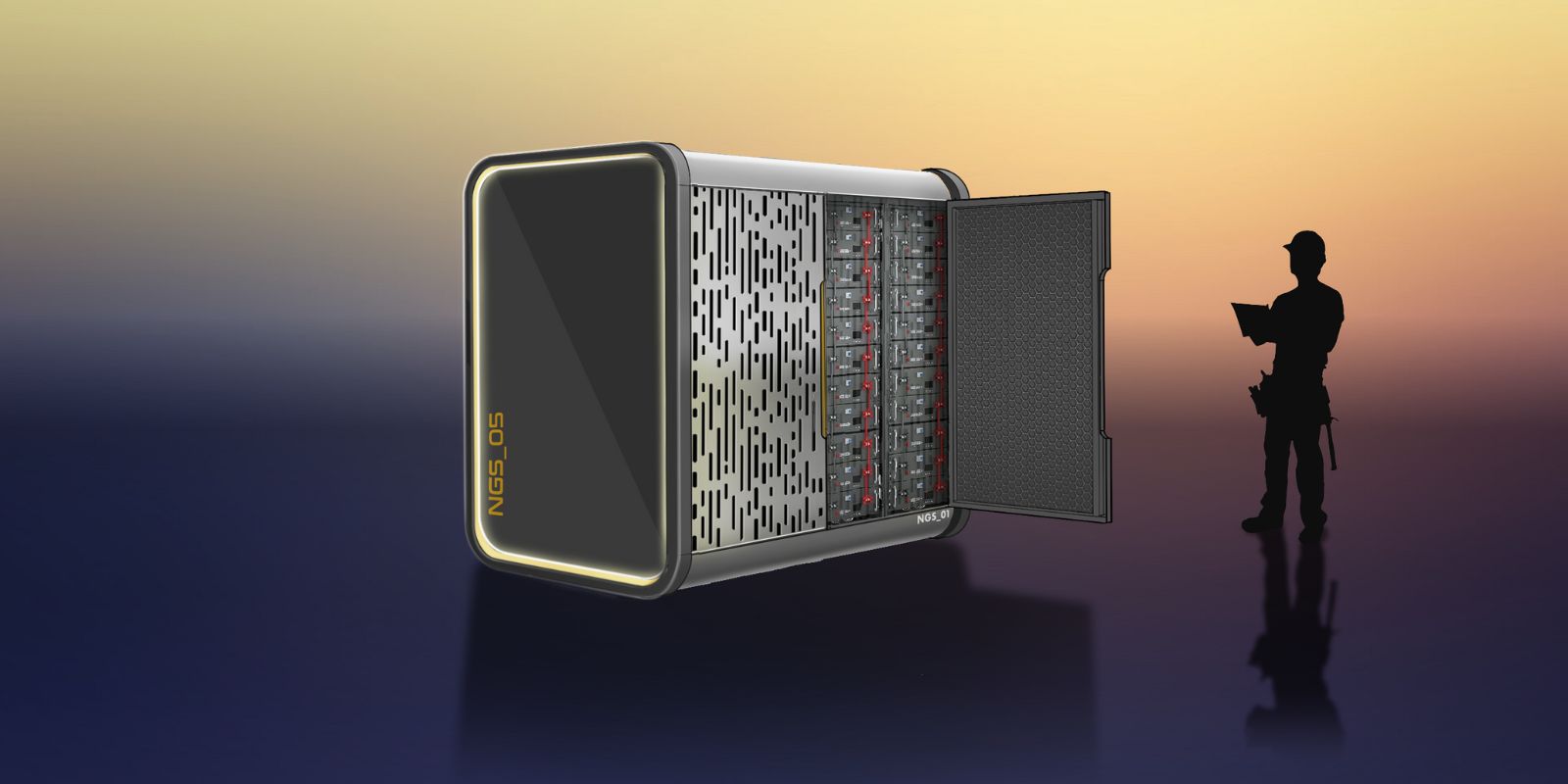

MCG is part of the consortium of the NGS – New Generation Storage project

To help develop a new technological ecosystem in the field of batteries that will elevate the Portuguese national industry in the global market.

MCG Experiences

MCG Employees review the Volkswagen T-Roc

Coming in direct contact with the car whose components they produce daily, and visiting the Volkswagen Autoeuropa factory.

MCG Automotive

Cost-effective and high-performance robotic processes in automotive component production

Stamping, cold forging, robotic MAG welding, machining, coating.

MCG Industry

Engineering and production partnerships with the customer

CountR relies on and collaborates with the MCG teams to engineer, manufacture, and enhance the next generation of CashIO Titanium casino machines.

MCG Automotive

Investing in technology, people, and processes

To strengthen the strong relationship with some of the world’s largest automotive component manufacturers.

Safety and Health at Work

MCG Safety First in 2023

The main priority at MCG: to ensure the Safety and Well-Being of all its Employees.

MCG History