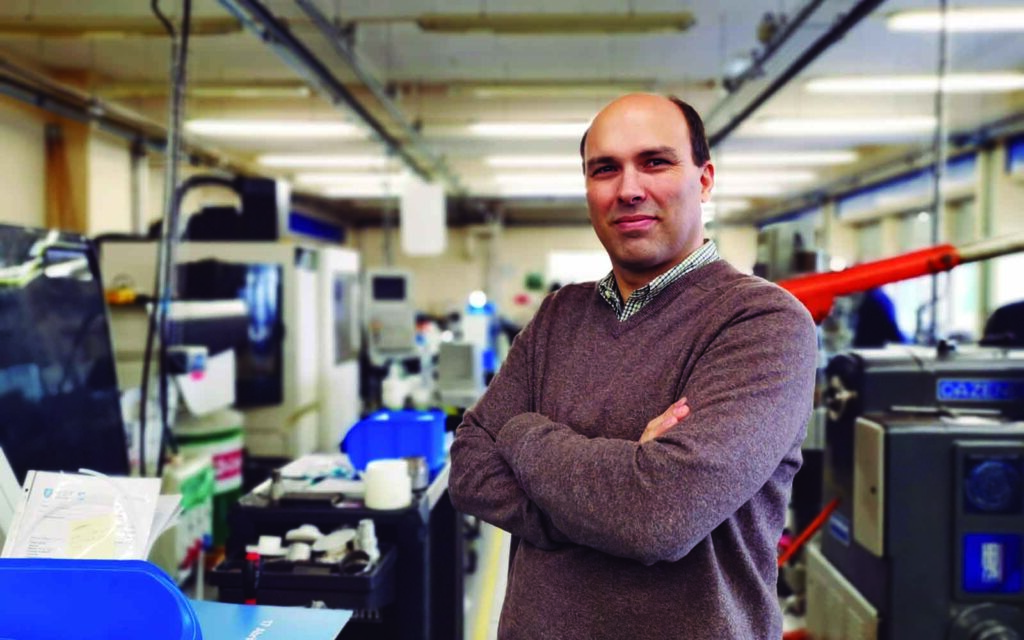

Professor Dr. Paulo Martins is one of the references of the Instituto Superior Técnico (IST), in Lisbon, a university highly regarded worldwide in mechanical engineering. And he is also a long-time friend of MCG, as he coordinates the company’s relationship with the Mechanical Engineering Department at that university.

Professor Dr. Paulo Martins tells us about the way MCG and IST collaborate on a regular basis, knowing in advance that MCG’s projects in the automotive industry are a real “school” for recent college graduates of mechanical engineering courses in the IST. But the foundations of this healthy and important relationship do not end there.

MCG: What kind of relationship does MCG have with IST?

Prof. Dr. Paulo Martins: The good relationship between the two entities happens at several levels. One aspect, although seasonal, is very important for us: several MCG employees participate as juries for the evaluation of our students’ master’s theses. This allows us to have industry feedback regarding our theses, just as it allows MCG to get to know some of our students. They are finalist students, so to speak, who will soon become engineers well prepared to enter the job market.

MCG: What about participation in MCG projects?

Prof. Dr. Paulo Martins:IST, more specifically our Mechanical Engineering department, is constantly involved in several MCG projects, such as the Modseat project, which was recently concluded by the hand of Engineer António Coelho in MCG transportation R&D activity.

There is also a relationship with Engineer Carlos Saraiva in terms of the current discussion of cases of innovation and technological processes, in addition to having a finite element program to support MCG’s tool development activity.

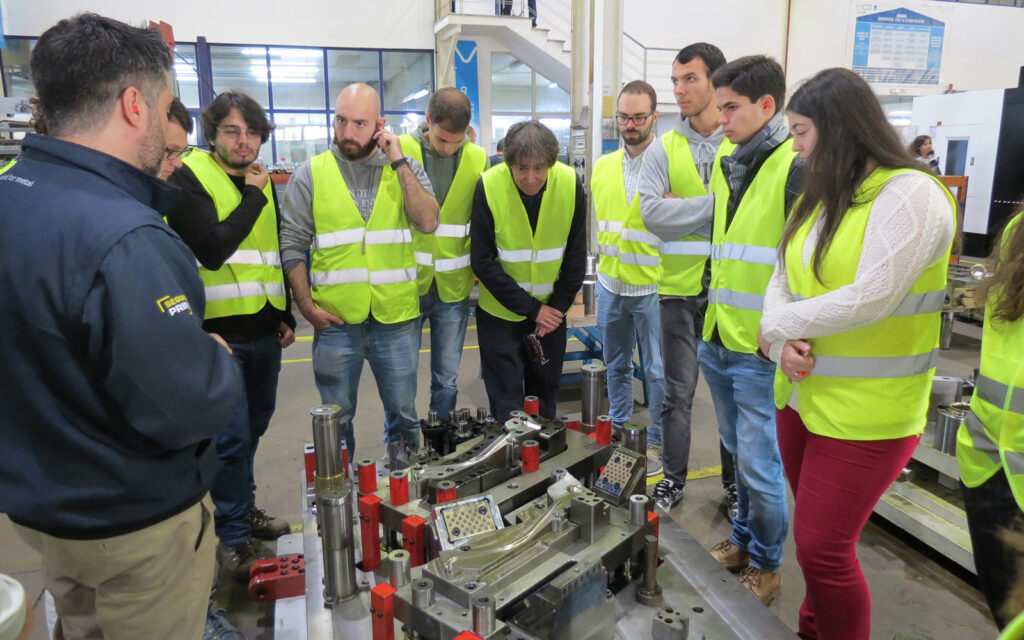

Collaboration with various sectors and in various activities thus allows us, for example, to take IST students to visit MCG frequently. In other words, IST’s relationship with MCG is vast, constant and mutual. I believe that MCG sees great advantages in this connection and for us, it is very important: it is the way of realizing that the works that we are developing are not disconnected from the industrial reality.

MCG: How can MCG be attractive to newly graduated engineers from IST?

Prof. Dr. Paulo Martins: The way I see MCG for a recent graduate is to be a great engineering school. It is the possibility for a young engineer to leave IST and join an organization that has great know-how in these areas, which turns out to be an enormous added value for our students.

There is always a challenge present: a company that is strongly linked to the automotive industry like MCG is always challenging for a mechanical engineer.

MCG: What is the profile of IST students who are most interested in MCG projects?

Prof. Dr. Paulo Martins: There are students who have a strong industrial DNA, these are always potential MCG employees. They end up showing a natural attraction for the company, as they have an appetite for industry, for production. MCG is very attractive here, yes, even worldwide.

Prof. Dr. Paulo Martins is a professor at the Department of Mechanical Engineering (DEM) and a researcher at the Institute of Mechanical Engineering (IDMEC), in IST, and is also an essential reference worldwide in production engineering research. He was recently appointed a Fellow of the International Academy for Production Engineering (CIRP), the leading global organization in his field, and has dozens of registered patents and published works.

MCG and IST: a historic partnership

Also within the scope of the Mechanical Engineering Department of the Instituto Superior Técnico (IST), this university maintains a Nucleus of Workshops that is supported by MCG.

MCG’s has been linked to the Instituto Superior Técnico (IST), one of the most respected universities in Europe in the fields of engineering for over three decades. More important than the longevity of the link, however, is the way in which both entities cooperate at various levels.

In addition to identifying promising engineers in the areas where MCG operates, this partnership extends to research projects in the field of plastic deformation and advanced machining technologies, and since 2012 it has supported IST’s experimental research technical activities through the Research Center. Workshops (NOF).

Likewise, since 2017, MCG’s support also targets the advanced training activities of LabM3 (Laboratory of Machining and Micro Manufacturing) in the field of machining processes.

Important for the students

Pedro Rosa opened the doors of these units to us, where even the uniforms of students and professionals are very similar to those of MCG Employees. According to the Coordinator of the Mechanical Engineering Department at IST, this long relationship is very important for students: “this is how we managed to fit the themes taught in mechanical engineering courses into the national industrial and business reality, as the activity helps to attract the best engineering students to the areas of production and mechanical technology ”..

Important for MCG

“It is natural that companies in the metalworking sector benefit from the integration of these engineers in internship programs and later in their staff, especially in the case of MCG, which has this close relationship with IST”, says Pedro Rosa, also stating that the big projects and clients that MCG works with today can be a major point of interest.

“An engineering professional is able to mentally dismantle any mechatronic system and the motivation to look for gaps that need innovation and improvement. These are characteristics that move the individual, making it closer to a highly competitive sport than to a profession. And MCG can provide that”.

For Pedro Rosa, the work the company does with IST is a path that must continue to be paved and whose success lies in “establishing a joint work plan”. It is certain that it will be so for MCG, since this is one of the “old formulas that have always worked and continue to work”.

Important: visits to IST and the respective interviews to create this article were conducted before the Covid-19 pandemic, which is why all participants appear in the photographs without the mandatory masks and safety distances.