Know-how and processes

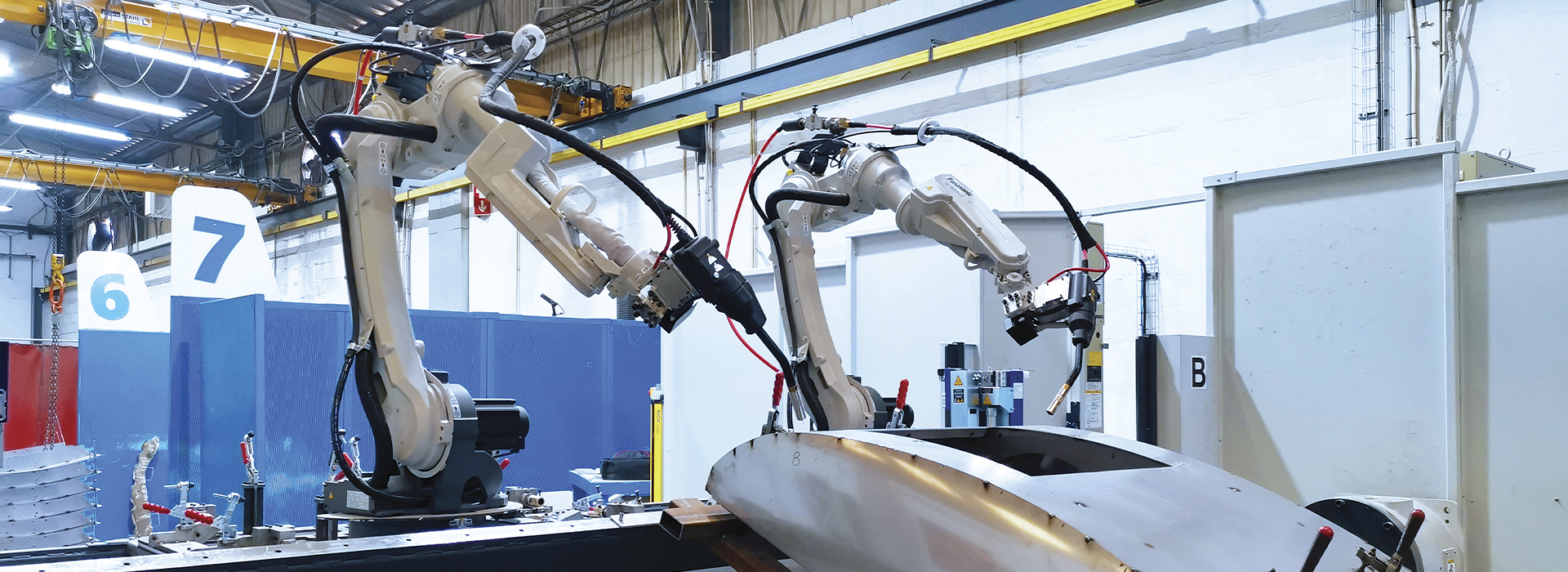

MCG industry Robotic Welding Technologies:

- Robots and welding machines with Super Active Wire technology, Touch Sensor (joint search), and Arc Sensor (joint tracking).

- Programming offline using the Panasonic DTPS program.

Welding Engineering:

- Development, manufacture, and inspection of welded joints.

- Development of welding jigs and sequencing of operations.

- Welding software (modeling, offline programming, process optimization, and simulation of welding cells).

Machinery and equipment

- State-of-the-art Panasonic robots and welding machines.

- Cells with positioners with a capacity of 1,000 kg.

- Robots mounted on rails four meters long.

Share