Project Overview

Objective:

Support ZF in the industrialization and serial production of a premium-quality suspension control arm, reaching 1.4 million units per year.

Approach:

Design and implement a fully automated, end-to-end manufacturing process – including stamping, cold forging, robotic MAG welding, precision machining, and advanced surface coatings – optimized for cost efficiency, resource management, and minimal waste.

Quality Commitment:

Ensure durability and safety standards required by global OEMs through 100% quality inspection and complete traceability.

Strategic Relevance:

Achieve above-average levels of excellence and quality in a component integrated into several high-end vehicles produced by the BMW Group.

Results

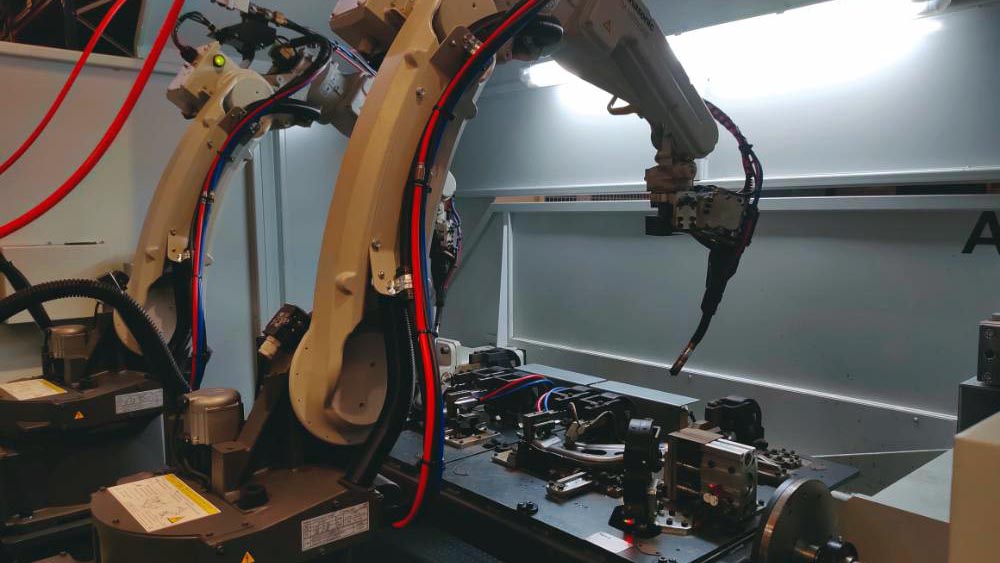

- Developed a robotic manufacturing ecosystem for welding and machining, ensuring process repeatability, reduced scrap, and 100% traceability.

- Delivered a scalable, cost-effective solution that seamlessly integrates all production stages and positions MCG as a trusted Tier 2 partner for critical chassis components.

- Strengthened MCG’s capabilities in selecting the right production technologies, managing outsourcing partnerships, and optimizing logistics and supply chain processes.

- Successfully consolidated serial production volumes at 1.4 million units per year.

Key Expertise

- Technical procurement & supply chain: Integrating external suppliers for sheet metal, cold-forged components, and surface treatments, while maintaining alignment with OEM quality standards.

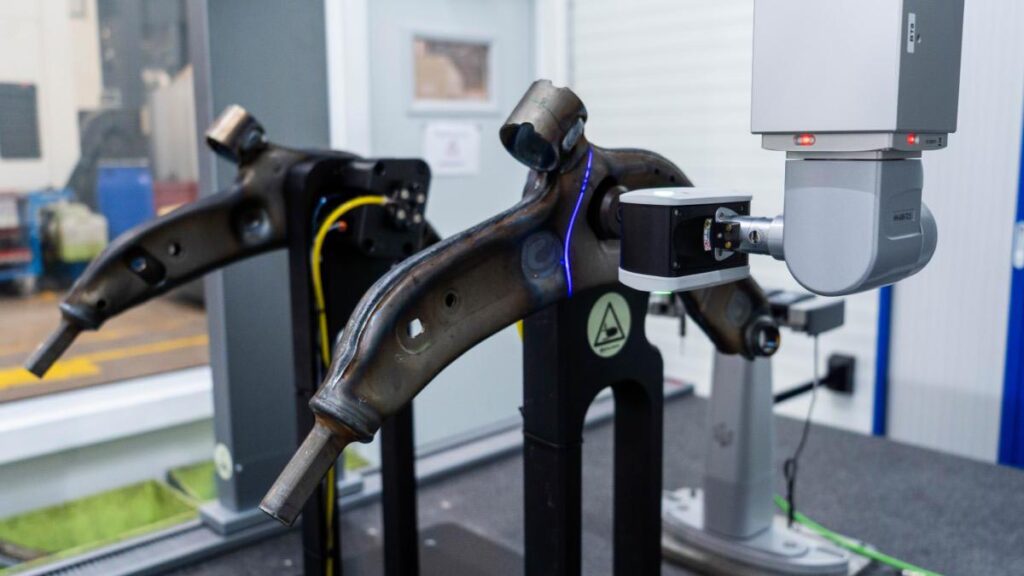

- Stamping of structural parts: Ensuring repeatability and dimensional accuracy in large-scale production.

- Robotic welding: Achieving consistent penetration and weld strength across long seams (~2 meters) in safety-critical components.

- Machining precision: Meeting tight tolerances required for assembly and vehicle performance.

- Surface protection: Managing advanced coating processes (ZnNi + KTL) to guarantee long-term corrosion resistance.

- Traceability & inspection: Implementing full unit traceability and AI-powered visual inspection systems.

- Logistics & customer integration: Synchronizing deliveries with Tier 1 and OEM schedules while balancing cost and efficiency.

Technical Information

- This assembly consists of two shells, upper and lower, cold-stamped from complex-phase sheet metal in a 3,300-ton press, one bushing sleeve also cold-stamped in a smaller press, and two cold-forged components.

- These are joined together by MAG welding, with a seam of almost two meters. There is also an in-line machining operation to ensure perfect matching and enhance weldability in the bushing sleeve area.

- For anti-corrosion purposes, the part is finally coated with a duplex-coating system with Zinc-Nickel and E-Coating (KTL), before being delivered to our customer.

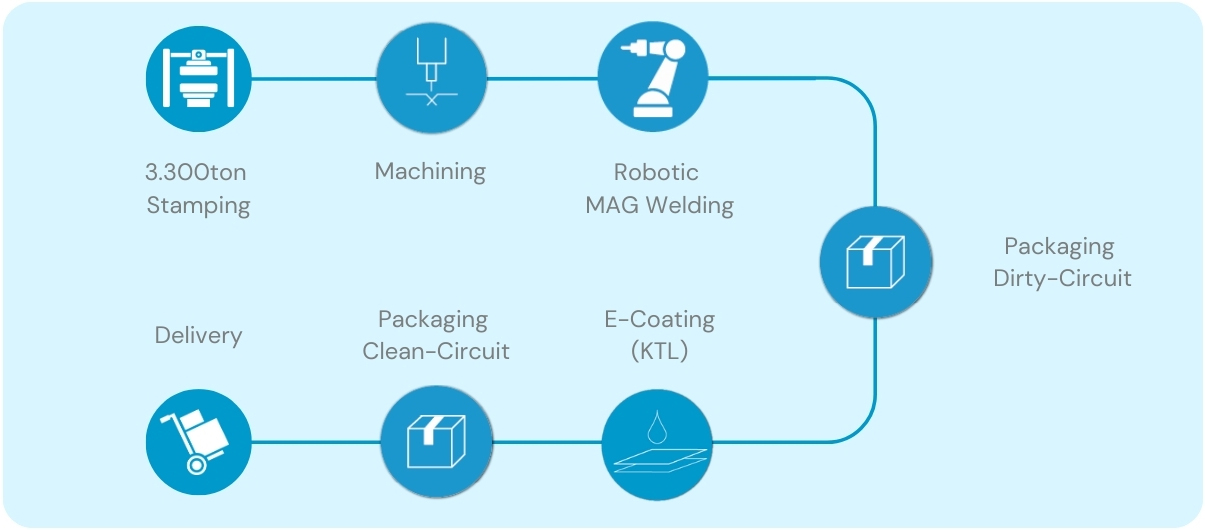

Manufacturing Processes

- 3.300-ton Stamping

- Machining

- Robotic MAG Welding

- Packaging Dirty-Circuit (before E-Coating)

- E-Coating (KTL)

- Packaging Clean-Circuit (after E-Coating)

- Logistics & delivery

Adrian Muñoz

Senior Manager Purchasing Buyer | ZF Group

“I started working with MCG ten years ago, and I´ve seen the company´s evolution in several ways. But I´m glad to see that commitment and professionalism have not changed.”

More information

Explore the project/component in the MCG Product Portfolio

Download the full MCG Case Study in PDF

Looking for a manufacturing partner that delivers precision, scale, and trust?

Looking for a manufacturing partner who delivers precision, scale, and trust?

Request contact from the MCG Sales Engineering Team:

João Porém

MCG Automotive Commercial Director

Pedro Carvalho

MCG Automotive Commercial Director