MCG continues to invest in the automation and optimization of its production processes at the MCG Automotive factories, raising standards of quality and efficiency. One of the best examples of this evolution is the project involving the production of a highly technical suspension arm, developed for ZF Friedrichshafen – Chassis Division and intended for BMW vehicles.

Reaching an annual production volume of 1.4 million units – its highest level to date – this project stands as one of MCG Automotive’s flagship operations.

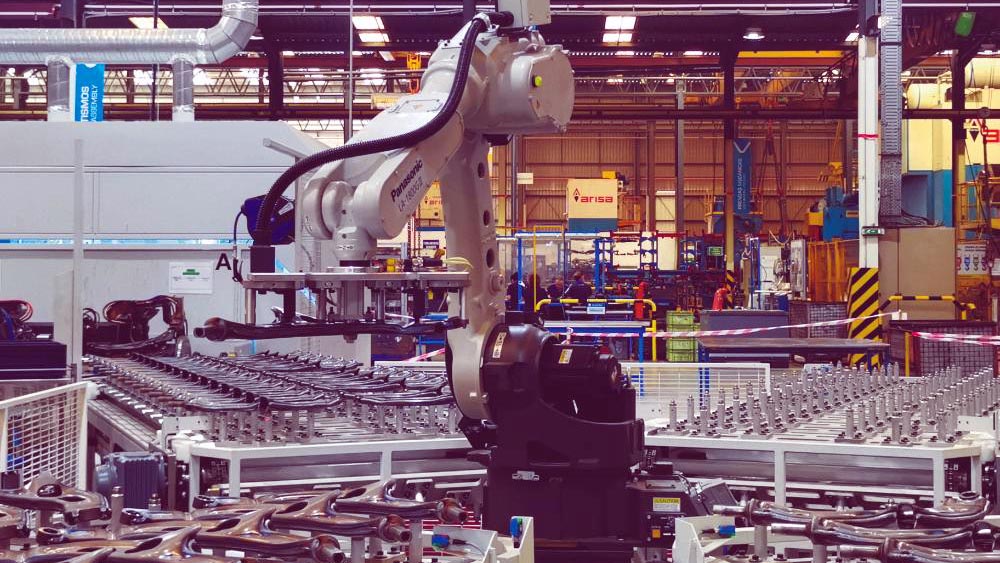

It seamlessly integrates a full manufacturing flow that includes 3,300-ton stamping, precision machining, robotic MAG welding, dirty-circuit packaging before E-Coating, KTL surface treatment, clean-circuit packaging post-coating, and coordinated logistics and delivery.

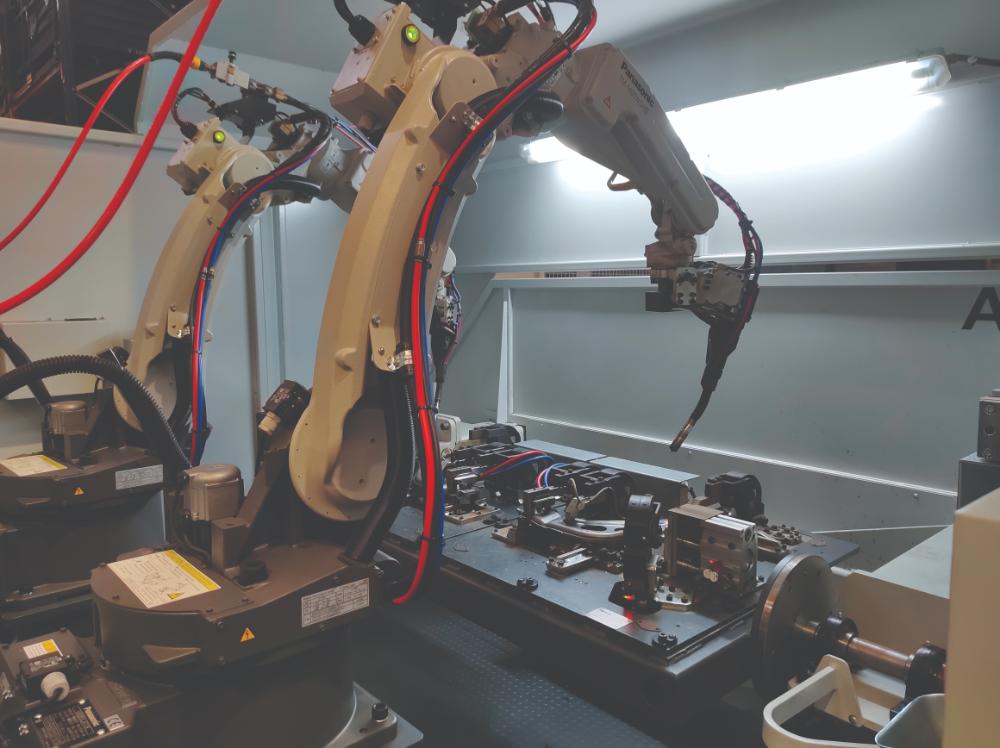

To achieve this milestone, the company implemented significant growth and investment in process automation and production equipment, including several new robotized welding and high-performance machining equipment.

Automation and productivity

In addition to the set of robotic welding cells, the introduction of new automatic transfer systems between stations allowed the optimization of the production flow, reducing human intervention and ensuring greater stability and productivity in manufacturing.

Furthermore, MCG implemented an advanced stoppage monitoring and management system, with in-house development of software, HMI hardware, and sensors, enabling easier identification of fault types, maximizing efficiency in troubleshooting, and productivity improvement.

Other important advancements are under development and implementation, particularly in equipment interventions. With the help of applications, technicians can quickly access checklists and tasks to be performed via QR codes, ensuring greater systematization of interventions.

Quality assurance

To gain flexibility and better responsiveness, MCG invested in an advanced Dimensional Quality Laboratory, with a new 3D measurement room and laser technology equipment, focused on this project.

This new quality laboratory significantly improves responsiveness to any deviations, minimizing the generation of non-conforming product and associated productivity losses.

Part of the investment supported by the PRR through the Hi-rEV project, this project consolidates MCG Automotive as a benchmark in the manufacturing of suspension arms for automobiles.