MCG continues to invest in the automation and optimization of its production processes at MCG Automotive factories, raising the standards of quality and efficiency. One of the best examples of this evolution is the ZF FAAR FLCA project developed by MCG for ZF: the production of a highly technical suspension arm for BMW vehicles.

In 2025, component sales related to this project may reach 1.4 million units, as the production lines dedicated to it are reaching their maximum output. This makes it one of the most significant projects in the 75-year history of the MCG Automotive business unit.

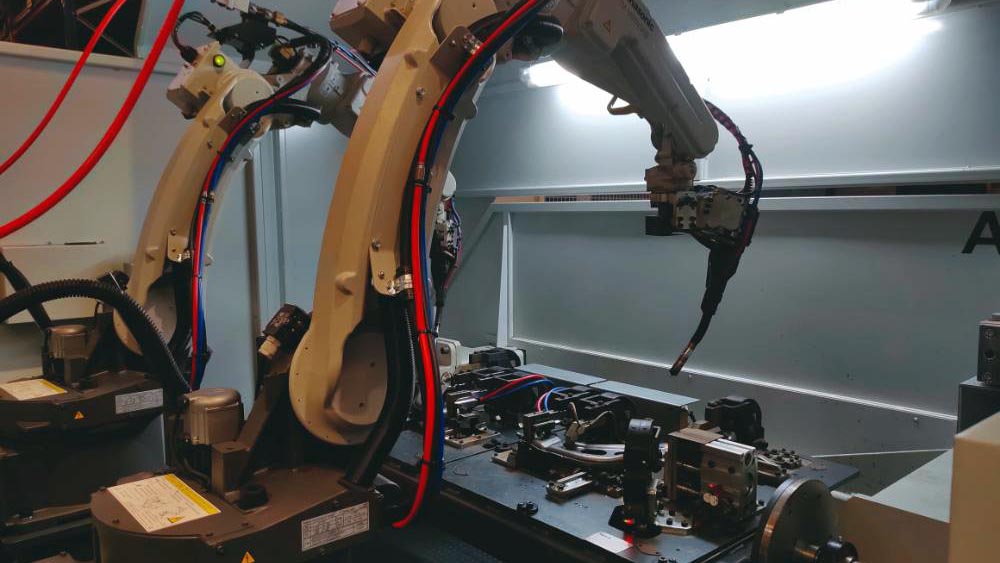

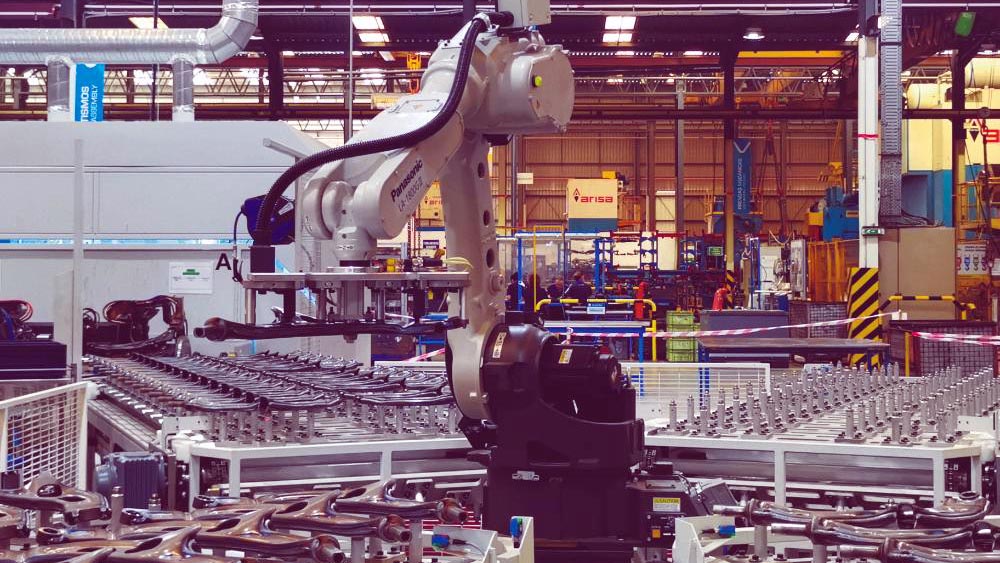

To achieve this level, the company has implemented significant growth in process automation, along with strong investment in production equipment. The final stage of this investment took place in 2024 with the acquisition and installation of another set of robotic welding and high-performance machining systems.

In this project, MCG has designed and implemented a production concept that carefully balances the following parameters: low cost, high-volume production capacity, component weight, sustainability, and recyclability.

The lower front control arm produced in this project:

In addition to the previously mentioned sets of robotic welding cells, the introduction of new automatic transfer systems between stations allows for optimized production flow, reducing human intervention by virtually 100% and ensuring greater stability and productivity in manufacturing.

Using technologies in which MCG is highly specialized — stamping, cold forging, MAG robotic welding, machining, and coating — this is a high-performance automatic manufacturing ecosystem, supported by rigorous quality control and traceability for each unit produced.

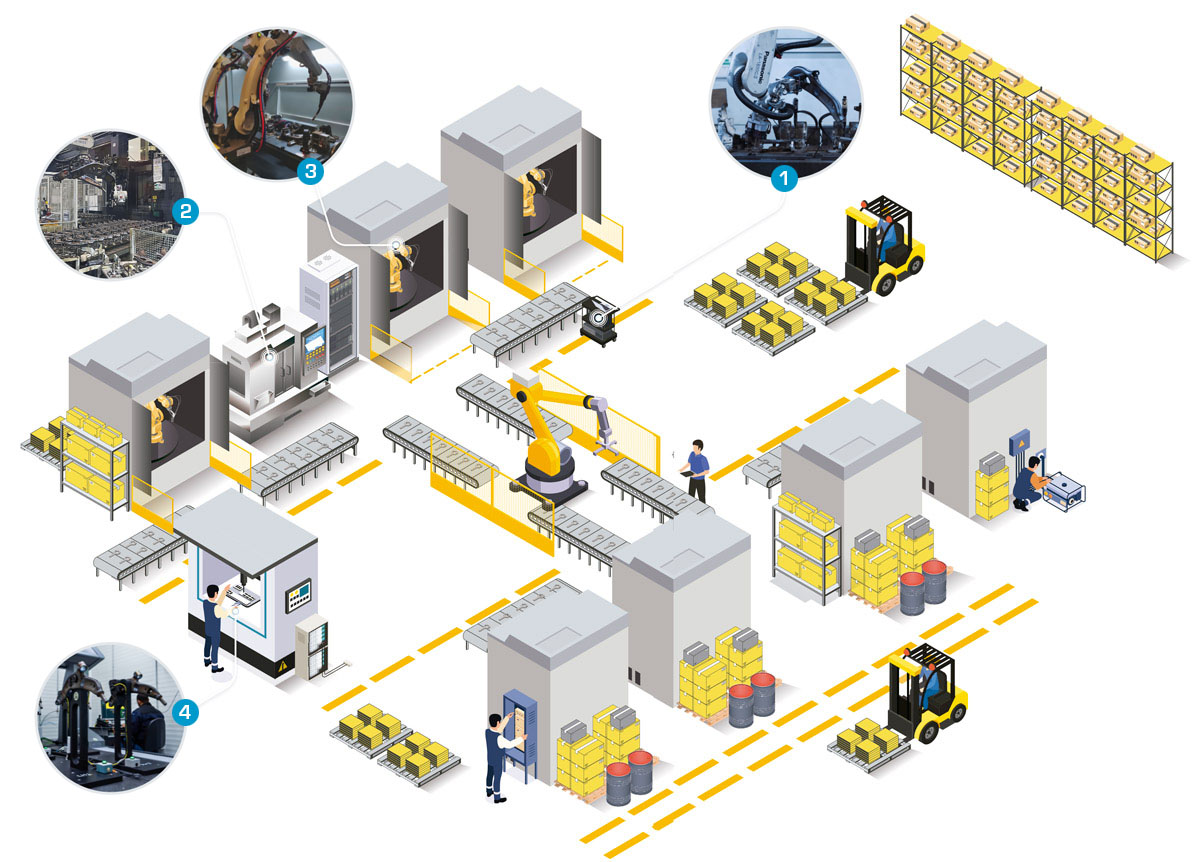

This illustration represents one of the several robotic welding stations that make up the production lines dedicated to the ZF project:

- The system is designed for large-scale production, incorporating Data Matrix marking technology and incoming readers at the entrance of each workstation. A unique “identity card” is generated for every part produced.

- Between welding stations and other elements of the production line, advanced machining centers apply complementary processes to the stamped and welded parts.

- The entire production flow features full automation between welding stations (featuring top-of-the-line Panasonic welding cells), eliminating human error and ensuring maximum safety standards.

- A precise quality control system aims to reduce the need for destructive testing to 100%, working in tandem with a weld penetration analysis system (macrography).

Videos showcasing all the processes, technologies, and expertise involved in this project:

Aqui entrará o novo vídeo ZF.

This entire production ecosystem is equipped with an advanced stoppage monitoring and management system, featuring in-house developed software, HMI hardware, and sensors. This setup enables easier identification of fault types, maximizing troubleshooting efficiency and improving overall productivity.

Other important advancements are under development and implementation, particularly in the area of equipment interventions. With the support of digital applications, technicians can quickly access checklists and assigned tasks via QR codes, ensuring greater systematization of maintenance operations.

Quality Assurance

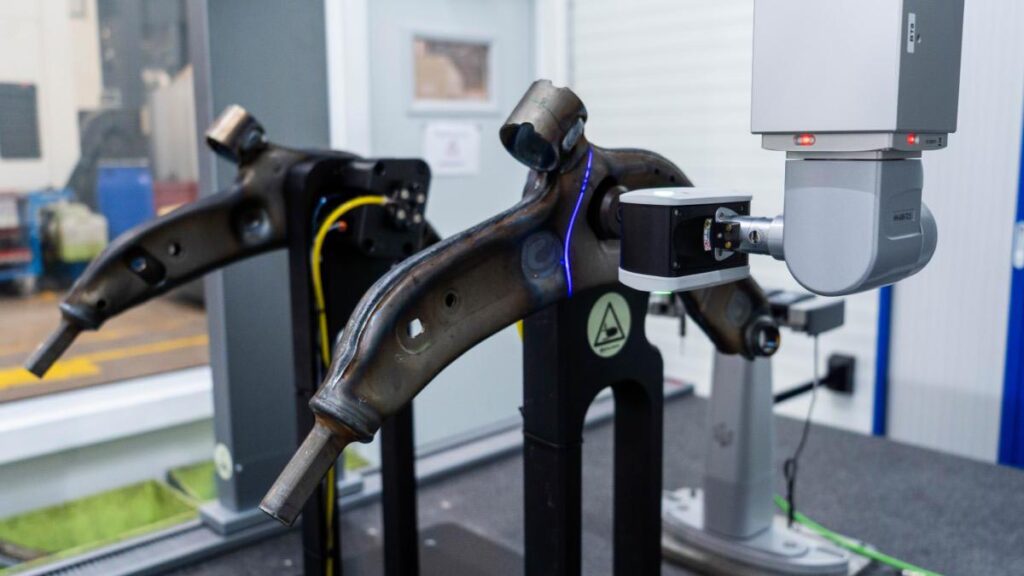

To enhance the flexibility and responsiveness of these production lines in terms of quality assurance, MCG recently invested in an advanced Dimensional Quality Laboratory fully dedicated to this project. The facility includes a new 3D measurement room and laser technology equipment.

This investment significantly enhances the ability to respond to any deviations, thereby minimizing the production of non-conforming parts and the resulting productivity losses.

The ZF FAAR FLCA project helps consolidate MCG Automotive as a global reference in the manufacturing of suspension arms for automobiles.

How the project evolved to reach the optimized production volume of 1.4 million units per year:

The PRR (the Portuguese Recovery and Resilience Plan) supported part of the investment through the Hi-rEV project.

More information and insights on the ZF FAAR FLCA project – the production of a suspension arm for ZF Chassis, intended for BMW vehicles:

- See the component in the MCG Product Portfolio

- View the full MCG Case Study on the project

For more technical and/or commercial information about this and other MCG Automotive projects, please contact:

Pedro Carvalho | Business Development, Strategic Account Management | MCG Automotive

João Porém | Business Development, Strategic Account Management | MCG Automotive